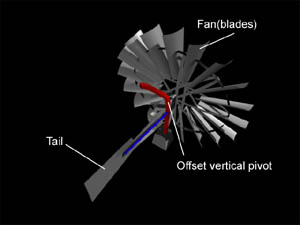

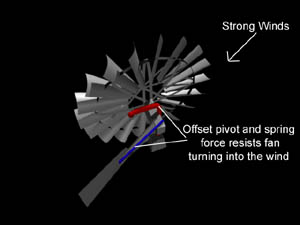

*How does the Lil' Jewell turn away from strong winds to prevent excessive speed?

High wind speeds create force on blades that rotates the fan about a virtual axis out of incoming wind. |

|

|

This lowers wind speed perpendicular to fan face, reducing rotational speed in hgh winds. Result is lower centrifical forces, increasing windmill life! |

*How and where are the windmills constructed?

*What is galvanized steel and how does it protect my windmill?

The material used in the construction of Jewell Windmills is ASTM A526 grade sheet steel. The Ultimate Tensile strength ranges from 42,000 – 54,000 psi. The blades and tail vane is constructed from 16 gage (0.059” thick) steel, twice as thick as the 20 gage (0.0359”) used by the original windmills! The blades actually increase in bending strength by a factor of 4 when the thickness doubles! This is definitely advantageous in a hailstorm! The framework utilizes 11 gage (0.1196”) steel and most other components are 14 gage (0.0747”).

A Galvanized proactive layer serves two main corrosive protective functions; Barrier and Sacrificial Protection. The barrier protection refers to film that stops oxygen and corrosives from reaching the steel surface. In addition to the barrier, the application of zinc supplies a ‘sacrificial anode’ for protection to the steel. Zinc has a higher electro-chemical potential (more active) then steel. When zinc and steel are in contact in an electrolyte, the zinc corrodes in preference to steel which is protected. It is this feature that enables zinc to protect steel at cut edges.

The heavy Z700 galvanized protective

coating used on Jewell Windmills is the thickest commercially

available! Z700 designates that 700 grams per square meter of

zinc is applied to the steel (both sides combined). This is

nearly triple the Z275 (G90) coating thickness you would find

on galvanized Roof and Siding applications and even heavier

then the Z610 coating on corrugated steel pipe culverts!

*How do the bearings work in the Lil' Jewell?

The two sealed pillow block bearings provide quite and smooth operation. Their low turning torque allows the windmill to spin in the lightest of breezes. The bearings are sealed and pre-greased. The bearings are enclosed for additional protection. Easy access is provided though the encloser for additional greasing in the future. Two axial locks are provided on each bearing unit to secure the 1” diameter fan shaft. Design life of the bearings are not limited by their rotational capacity. In fact, according to the manufacturer’s literature, the bearings will survive 28 years at a constant wind speed greater then 10 miles per hour for the supported weight.